產品詳細介紹

PFC 兩片式浮動Direct Drive™街道升級碟盤技術

自從碟盤被發明以來,由於熱膨脹(盤片翹起)引起的振動一直是一個主要問題,直到現在...

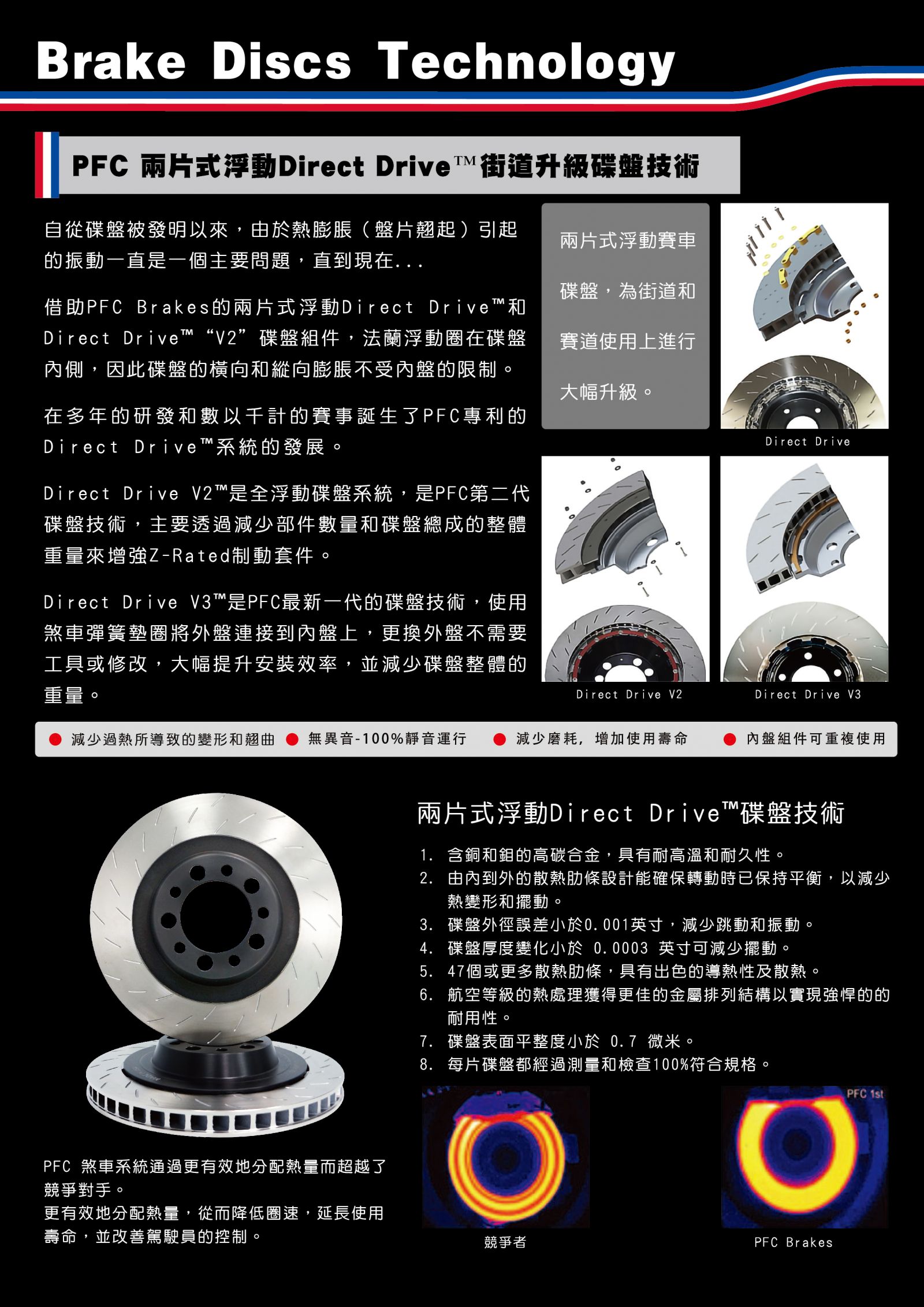

借助PFC Brakes的兩片式浮動Direct Drive™和Direct Drive™“V2”碟盤組件,法蘭浮動圈在碟盤內側,因此碟盤的橫向和縱向膨脹不受內盤的限制。

在多年的研發和數以千計的賽事誕生了PFC專利的Direct Drive™系統的發展。

兩片式浮動賽車碟盤,為街道和賽道使用上進行大幅升級。

|

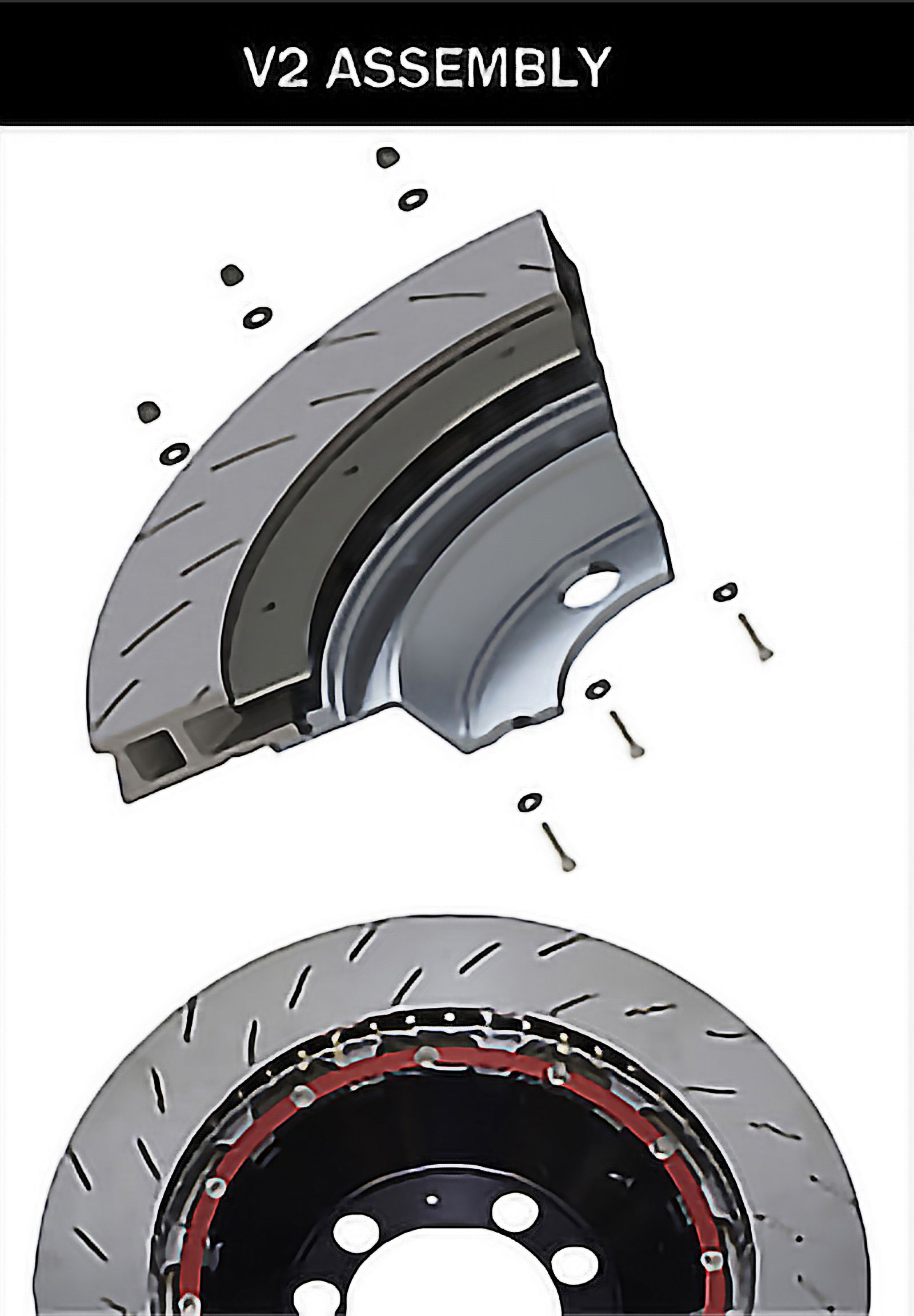

Direct Drive V2™ 是全浮動碟盤系統,是PFC第二代碟盤技術,主要透過減少部件數量和碟盤總成的整體重量來增強Z-Rated制動套件。 |

|

|

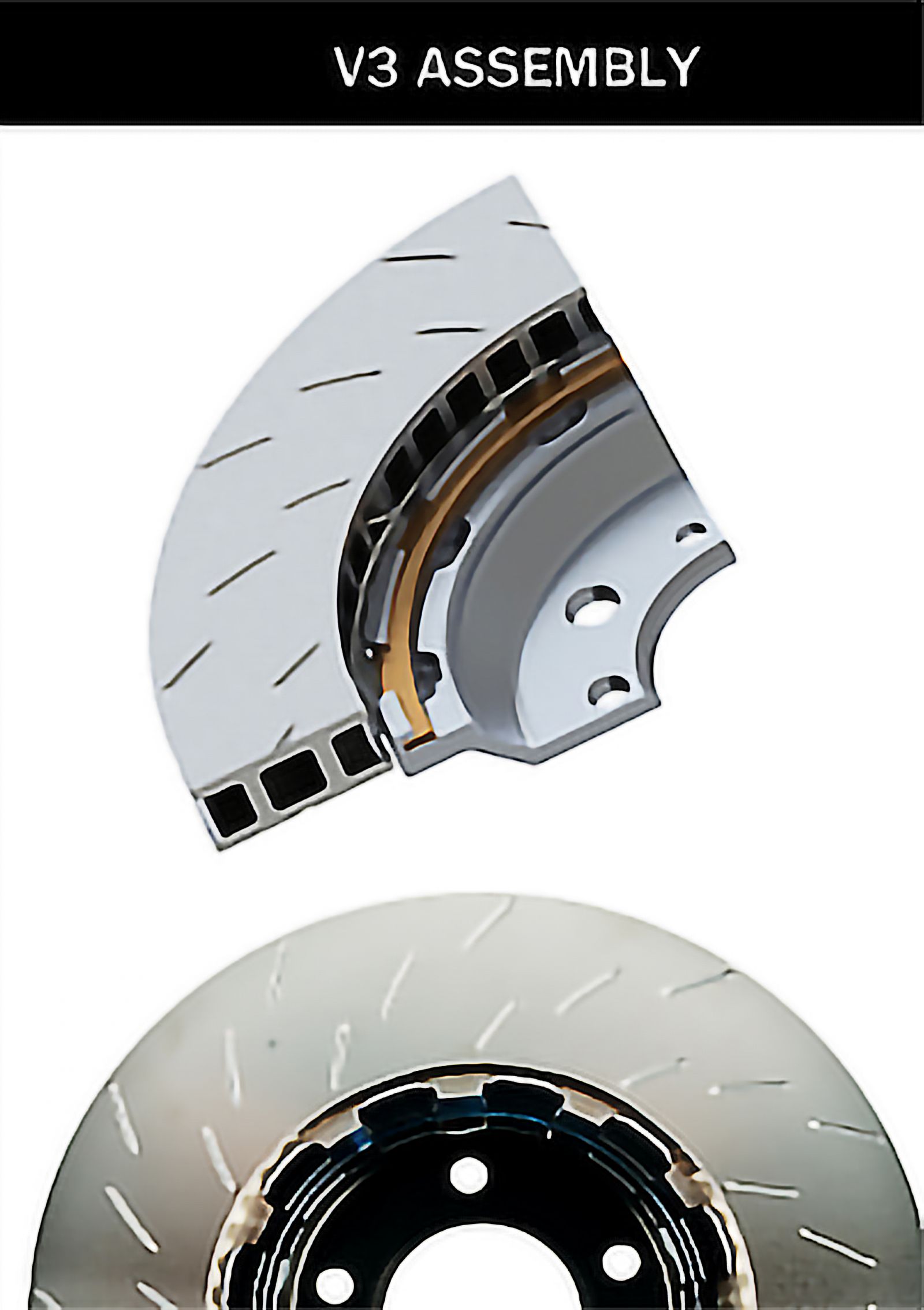

Direct Drive V3™ 是PFC最新一代的碟盤技術,使用煞車彈簧墊圈將外盤連接到內盤上,更換外盤不需要工具或修改,大幅提升安裝效率,並減少碟盤整體的重量。 |

| ● 減少過熱所導致的變形和翹曲 | ● 無異音-100%靜音運行 | ● 減少磨耗,增加使用壽命 | ● 內盤組件可重複使用 |

兩片式浮動Direct Drive™碟盤技術

1. 含銅和鉬的高碳合金,具有耐高溫和耐久性。

2. 由內到外的散熱肋條設計能確保轉動時已保持平衡,以減少熱變形和擺動。

3. 碟盤外徑誤差小於0.001英寸,減少跳動和振動。

4. 碟盤厚度變化小於 0.0003 英寸可減少擺動。

5. 47個或更多散熱肋條,具有出色的導熱性及散熱。

6. 航空等級的熱處理獲得更佳的金屬排列結構以實現強悍的的耐用性。

7. 碟盤表面平整度小於 0.7 微米。

8. 每片碟盤都經過測量和檢查100%符合規格。

|

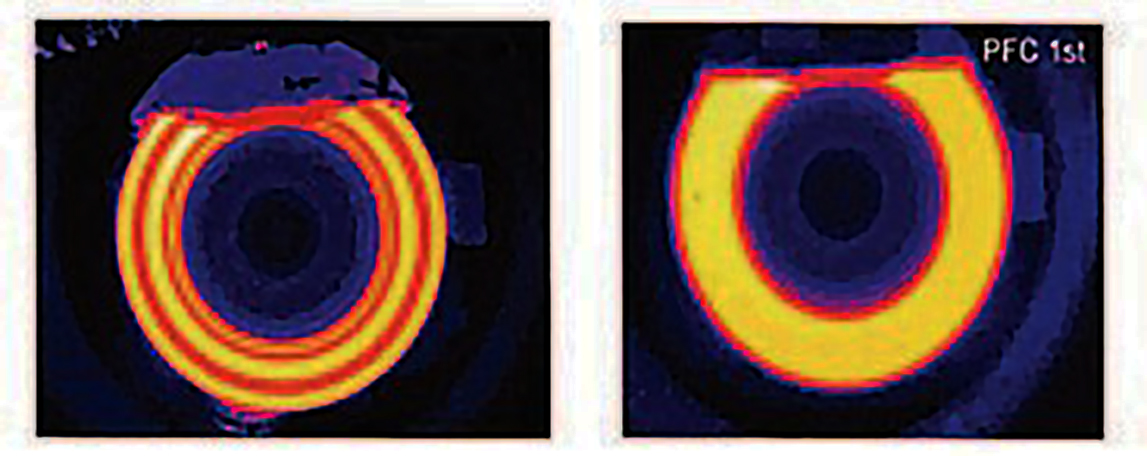

PFC 煞車系統通過更有效地分配熱量而超越了競爭對手。 更有效地分配熱量,從而降低圈速,延長使用壽命,並改善駕駛員的控制。 |

|

Two-Piece Floating Direct DriveTM Street Upgrade Disc Technology

Ever since the disc brake was invented vibration and pulsation caused by thermal expansion (warped discs) has been a major issue.

Until Now…

With Performance Friction’s two-piece floating Direct Drive and Direct Drive ‘V2’ disc assemblies, the disc flange floats in the bobbin structure, allowing radial and axial expansion of the disc without being constrained by the hub or hat.

Years of R&D and thousands of race miles have resulted in the development of PFC’s Patented Direct DriveTM Systems.

A true two-piece floating race disc optimized for road and track duty.

|

Direct Drive V2™ is an integral drive in hat system and is a second generation disc mounting system designed to enhance the Z-Rated Big Brake kits by reducing the number of components and overall disc assembly weight. |

|

|

Direct Drive V3™ is the very latest generation mounting system that uses a spiral locking ring that connects the disc to the hat - allowing much faster fitting without the need for tools or fixings, and producing even less overall weight. |

| ● Reduced thermal distortion and warping. | ● No rattling – 100% silent operation. | ● Reduced drag and increased mileage. |

● Reusable hat/hub assembly. |

Direct Drive™ Discs

1. High Carbon Alloy with copper and molybdenum for high temperature strength and durability.

2. Vanes turned OD and ID for balance to reduce thermal warping and vibration.

3. Run-out less than .001 inches, reducing pulsation and vibration.

4. Thickness variation less than .0003 inches reduces vibration.

5. 47 or more vanes for superior thermal capacity.

6. Aircraft quality heat-treated for microstructure alignment and durability.

7. Surface fi nishes less than .7 microns.

8. 100% measured and inspected to meet tolerance specifi cations.

| The Result... PFC Brakes outperform the competition by more effi ciently distributing heat for lower lap times, longer life and improved driver control. |

|